Service

Our "FFP" (FUJIMAKI FREESIZE PLATES) is a 24-hour custom-made steel plate production service

that enables rationalization and labor-saving for your successful business.

We perform surface grinding, finishing, and secondary processing at a precision you desire.

Custom-made steel plate production services enhances your creativity

Regardless of the kinds and brands of materials, we provide you with plates exactly as indicated in the design drawing.

In accordance with your request, we perform processing with an extremely high level of skills and technology, and deliver products with no delay.

The biggest advantage of this flexible service is that you don't need to perform surface grinding and finishing.

As a result, you don't have to invest on equipment and specialists.

Furthermore, the 24-hour production system enables supplying at the time you need.

Hence, you don't need to hold stock, either.

In this way the FFP service enables drastic rationalization and labor-saving as well as focusing on creativity.

Count on us for your product with better quality.

-

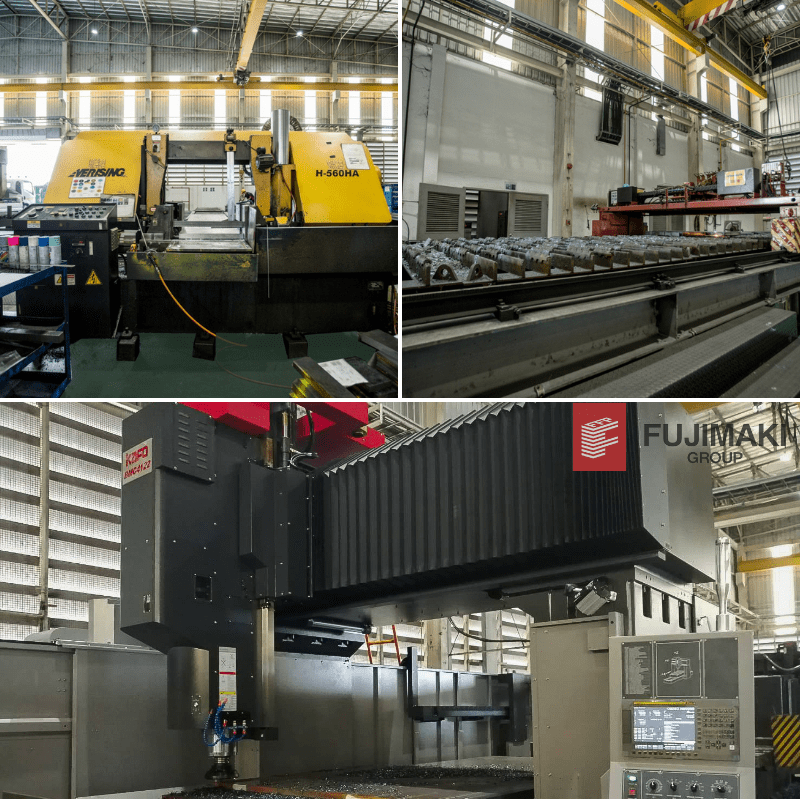

Order

-

Processing

-

Inspection

-

Delivery

-

HEAT TREATMENT

Quenching + Tempering

To harden steel, steel is heated and held above a predetermined temperature and then quenched with water, oil, etc.

After quenched, reheat to a specified temperature to enhance toughness.Annealing

Steel is heated and held above a predetermined temperature and then slowly cooled.

Eliminate stress and magnetic force in steel, make it softer and easier to process.Sub-Zero Treatment

To reduce size aging, quenched steel is cooled below 0°C to reduce the amount of microstructurally unstable material that is often present in the interior.

Vacuum Treatment

A vacuum pump is used to reduce the pressure inside the furnace to heat treat steel.

Oxidation of the steel is suppressed and a shiny appearance is obtained.Surface Treatment

Surface treatment by quenching hardens the surface of steel and improves its wear and fatigue resistance.

Heat Treatment Pic-up and Delivery Service

Pick-up and deliver Heat Treatment products in dedicated vehicles.

-

COATING

PVD Coating

Use electrical energy in a high-temperature vacuum to form films at the atomic and molecular levels.

Nitriding

Infiltrate steel with nitrogen to form nitrides on the surface.

Chrome Plated

Electroplate a thin layer of chrome on the surface of steel.

Teflon Coating

Apply fluororesin to the surface of steel.